Clarity, Compliance, and Confidence in Your Process Systems

In the world of industrial facilities and process engineering, accurate, robust, and up-to-date documentation is not just a best practice—it’s essential for safety, compliance, and operational excellence. At VITOK Engineering, we specialize in developing and reviewing Process Flow Diagrams (PFDs) and Piping & Instrumentation Diagrams (P&IDs), two foundational documents that provide the blueprint for your plant’s processes and control systems.

Whether you’re building a new facility, planning an expansion, addressing regulatory requirements, or seeking to optimize existing operations, our team has the experience and industry knowledge to deliver solutions tailored to your facility’s unique needs.

What Are Process Flow Diagrams (PFDs)?

Key Features of PFDs:

- Identification of major equipment (tanks, pumps, reactors, heat exchangers, etc.)

- Simplified process lines showing the flow of materials and utilities

- Information on key operating parameters (temperatures, pressures, flow rates)

- Overview of major control strategies or process interlocks

- Basis for mass and energy balance analysis

- Useful for both new builds and revamp projects

Why PFDs Matter:

- Design Basis: PFDs are the starting point for both new facility construction and process improvements in existing plants. They provide essential context for detailed engineering, planning, and procurement.

- Regulatory Compliance: Many regulations (such as OSHA’s Process Safety Management, or PSM, standard) require facilities to have up-to-date PFDs for covered processes.

- Efficiency & Troubleshooting: Clear process flow diagrams enable teams to quickly identify bottlenecks, inefficiencies, or safety vulnerabilities.

- Communication: They serve as a “common language” across multidisciplinary teams—bridging process, mechanical, electrical, and controls engineering.

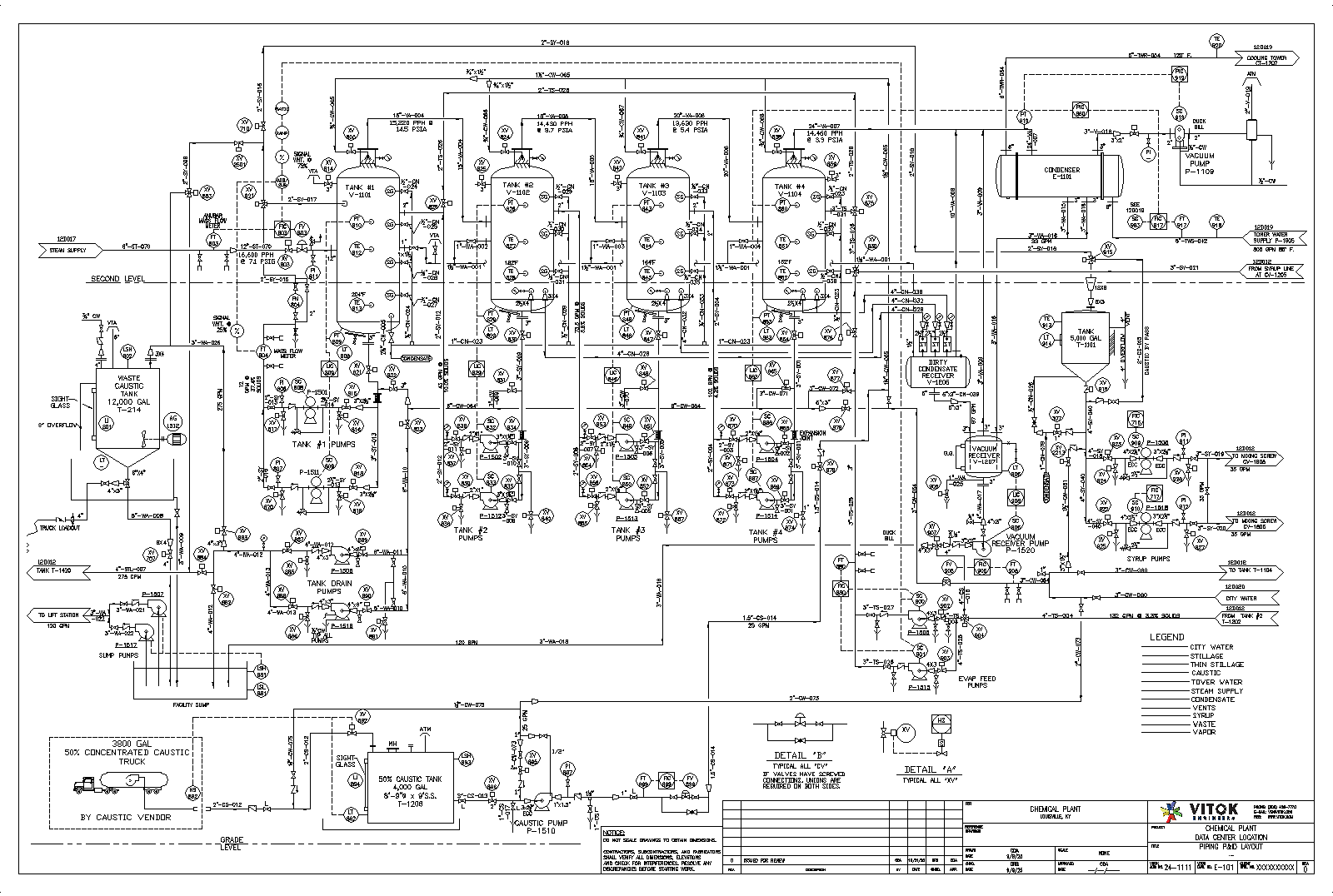

What Are Piping & Instrumentation Diagrams (P&IDs)?

Key Features of P&IDs:

- Detailed depiction of process and utility piping, including sizes and specs

- Precise location and specifications for every valve, instrument, sensor, and control device

- Interconnection details for automation, including setpoints, alarms, and logic

- Materials of construction, line labeling, flow directions, and insulation details

- Clear indication of all relief devices (relief valves, rupture discs, etc.)

- Identification of safety interlocks and shutdown systems

Why P&IDs Matter:

- Operational Safety: P&IDs are essential for maintenance, operation, modification, and safe shutdown of the facility.

- Code Compliance: Regulatory frameworks (OSHA PSM, API, ASME) mandate thorough and up-to-date P&IDs, particularly for high-hazard and chemical processing facilities.

- Troubleshooting: When unexpected events occur, accurate P&IDs can be the difference between swift remediation and prolonged downtime.

- Process Optimization: For expansions, retrofits, or equipment replacements, the P&ID is the definitive reference for what currently exists and what must change.

VITOK’s Expertise in PFD & P&ID Services

VITOK provides comprehensive support throughout the documentation lifecycle—whether you are starting from scratch for a new facility, updating or reconstructing diagrams for an existing plant, responding to audits, inspections, or regulatory inquiries or planning a capital improvement or modernization initiative.

PFD Creation and Review

We work with your engineering, operations, and maintenance teams to accurately capture your process flows, using your data and our expertise to create clear, compliant diagrams.

P&ID Development and Verification

Our team identifies, documents, and details every process and utility connection, leveraging site walks, interviews, and legacy drawings where needed.

Gap Assessment

Not sure if your existing documentation meets current standards or accurately reflects your plant? We assess, update, and validate your PFDs and P&IDs, minimizing compliance risk.

Process & Instrumentation Consulting

Beyond drawing diagrams, we provide engineering insight—like identifying where safety instrumented systems (SIS), high-integrity protective systems (HIPS), or hazard analysis should be implemented.

Training & Knowledge Transfer

We support your team with training sessions on reading and interpreting PFDs and P&IDs, so knowledge stays with your staff for long-term reliability.

![Worker Documenting Piping 1920x1280[80] Distillery Design: Featured Image](https://vitok.com/wp-content/uploads/2025/12/Worker-Documenting-Piping-1920x128080-1.jpg)

Customized Approach for Every Facility

Every facility is unique—whether it’s a major chemical plant, a specialty manufacturer, or a food & beverage operation. VITOK recognizes that one-size-fits-all solutions don’t work for process documentation. We bring decades of hands-on experience across industries to identify what matters most for your facility, ensuring clear diagrams, practical recommendations, and actionable documentation.

Already Have PFDs or P&IDs?

We review, update, and validate your existing documentation to reflect process changes, expansions, or code updates. Our team can help digitize or standardize legacy documentation, ensuring you are always “audit-ready.”

No Documentation in Place?

VITOK excels at site discovery—asking the right questions, collaborating with your in-house experts, and using field verification to build diagrams from the ground up.

Why Choose VITOK For Process Documentation?

- Regulatory Awareness: We keep up with evolving codes (OSHA, API, ASME, NFPA, etc.)—so you stay compliant.

- Collaborative & Responsive: From kickoff to completion, our engineers engage with your team to keep documentation accurate and practical.

- Safety & Performance: Our PFDs and P&IDs don’t just check compliance boxes—they drive operational integrity and ongoing plant improvement.

- Trusted by Industry Leaders: Our longstanding client relationships are built on a track record of solving tough process challenges.

Ready to Get Started?

Empower your operations with clear, compliant, actionable process documentation. Contact VITOK Engineering today to learn how our PFD and P&ID services can improve plant safety, streamline expansions, and keep your facility ahead of compliance requirements.