Our team was able to utilize both our experience and multi-discipline advantage to get this process up and running.

In 2016, we made a promise – to bring 21st century technology and knowhow to Stanford and build a new farm so advanced that it could inspire many more people to change the world in a positive way. Along the way we faced regulatory roadblocks and engineering obstacles and we came to understand that to keep this promise, we needed to find a local engineering partner that shared our values. I’m pleased to say that we found that partner in VITOK Engineers, and we haven’t looked back since. Their team took the time to learn about our operation and the challenges we faced on an extremely detailed level and developed a comprehensive, multi-stakeholder strategy to see us through the storm. They have been an integral part of completing our heating and electrical systems, our irrigation and CO2 systems, our power upgrades and they have even provided outstanding construction management services as we needed it. With VITOK’s help, we are keeping that promise to our community and, in the process, making improvements to the efficiency of our systems that will pay dividends for years to come.

Curt Meltzer – CEO KY Fresh Harvest

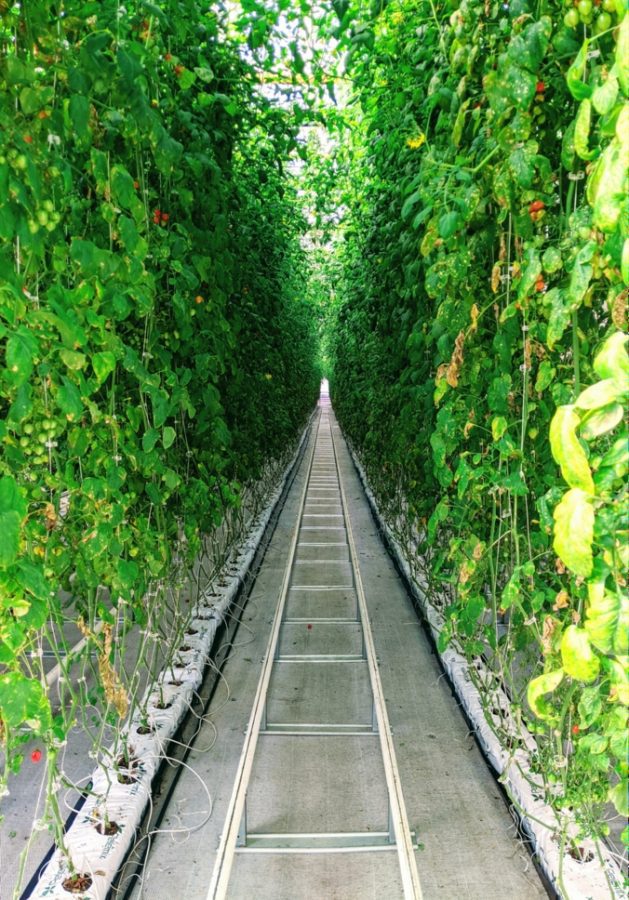

VITOK Engineers has had over five decades of experience designing various chemical plants, distillation systems, and manufacturing facilities. This experience lends itself to an up-and-coming agricultural industry that is rapidly evolving with state-of-the-art technology and a new set of standards. This new agriculture is designed to optimize every square foot of growing space, every ounce of water, and every drop of nutrients.

VITOK Engineers was contacted by Kentucky Fresh Harvest to assist in structural engineering, power distribution, controls, and project management support. After reviewing the Carbon Dioxide management, lighting optimization, water management, and heat requirements for the facility, it rapidly became evident that we needed to employ our Process Engineers on the project, for there were many separate subsystems that we not coordinated to make the facility operational. We then quickly developed Process Flow Diagrams (PFDs) and Process & Instrumentation Diagrams (P&IDs) to get these systems in order.

The PFDs and P&IDs assisted with the planning, construction, automation, and startup of the facility. Since the availability of power to support all of the equipment was a problem, we worked with the local utility to get the required power fed to the facility and designed the power distribution system to get this power to the necessary locations.

Finally, we utilized our Project and Construction Oversight Manager to help pull all of the resources together. This project was on a tight timeline to meet a planting window for the season, so all of the installation components needed to be completed on time.

- Structural Engineering

- Process Engineering

- Electrical Engineering

- Instrumentation

- Process Automation

- Project Management

- Construction Oversight

Kentucky Fresh Harvest Website